- Specifications of acid-resistant tiles:

- - Resistant to acids

- - High mechanical resistance- High resistance to wear

- Has high abrasion resistance

- - Very low water absorption and high resistance to frost

Isfahan, Chaharbagh Bala, Kavian Alley, No. 45

Tel: +98 -31- 36248019 Fx: +98 -31- 36240642

Email: export@marjantileco.com

Applications :

Important points in choosing industrial acid-resistant tiles are as follows:

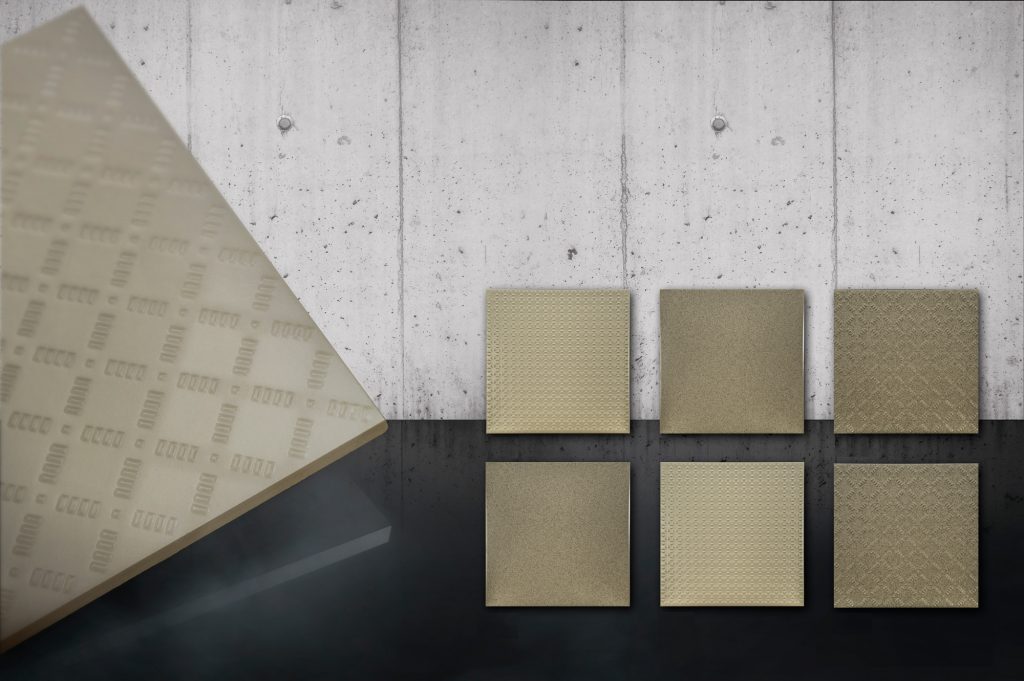

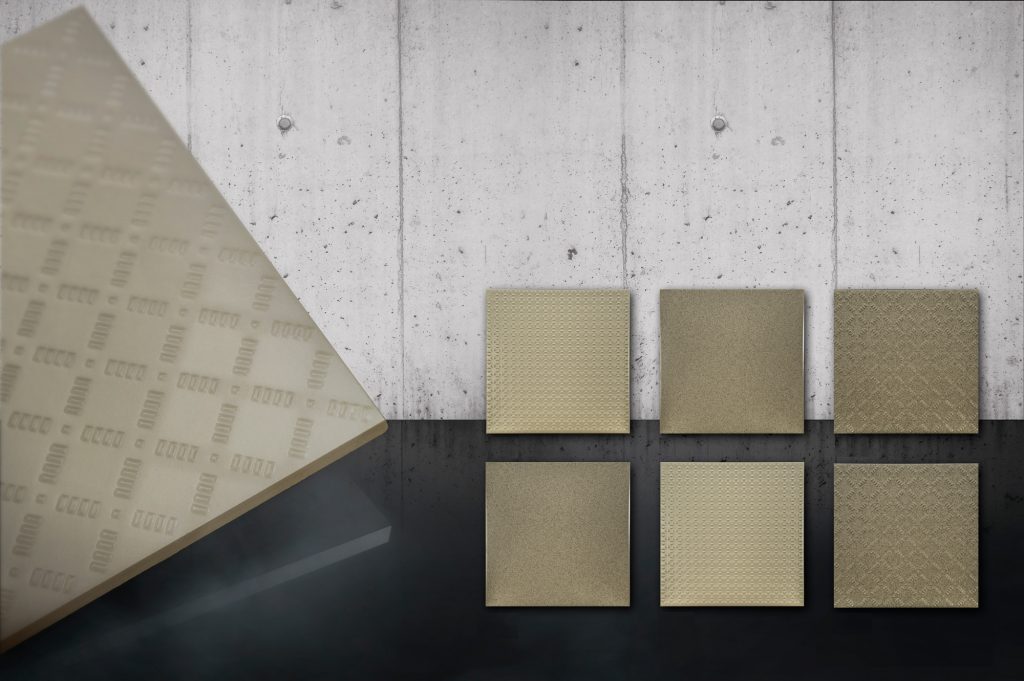

- For floors in environments where slipping is possible, and as a result, there is a risk of people falling, be sure to use the type with texture or in other words, anti-slip products.

- In industrial spaces where there is an excessive presence of dirtying agents, it is recommended to use red-grain acid-resistant tiles that have a higher dirt-repellent property compared to plain types.

Installation of industrial acid-resistant tiles: To benefit from the positive features of acid-resistant tiles, it is essential to observe the following points during installation: